20

10

30

Diagram 1. Large Green Brick (Walls)

Dimensions in cm

green brick (diagram 4, p19) which is

used for the roof. Once the mixture

has been beaten the bricks can be

formed in one of two ways:

Method 1. Removing water in the

moulding cast: Slope Moulding

The metal or wooden moulding casts

must be washed and cleaned in a

bucket or container full of water. Next,

the mud must be cut and shaped in

the moulding cast, before the cast is

removed. The mud should be one

firm piece with no signs of cracks

or unevenness. The mud should be

pressed so that there are sharp well

defined corners.

14

Practical Answers Sudan

The Construction of the Timberless House Model

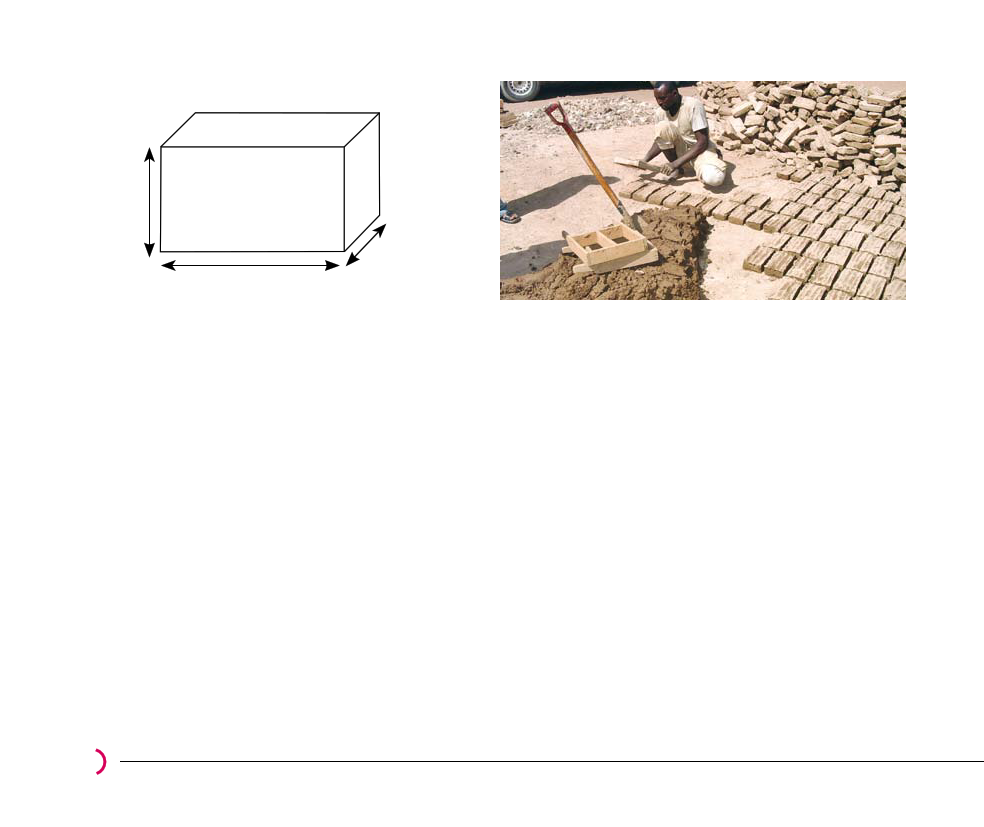

Pic 4. A participant using a moulding cast for brick production

Method 2. Removing water using sand: Sand Moulding

Once again the cast should be cleaned in water in a bucket

or container. This time the mould is lined with sand to form

an insulated layer so the mud can slide out easier when the

mould is lifted. This gives the brick extra quality and more

rigid edges. However the downside of this technique is that it

is slower so invariably the builders prefer the first method.

Drying the bricks is the next stage and is considered a key

part of the brick making process. The bricks should be left in

the open air to dry for a total of three days until all the water

dries out. It is better that the bricks are made at the same

building site so that they do not crack while being moved.